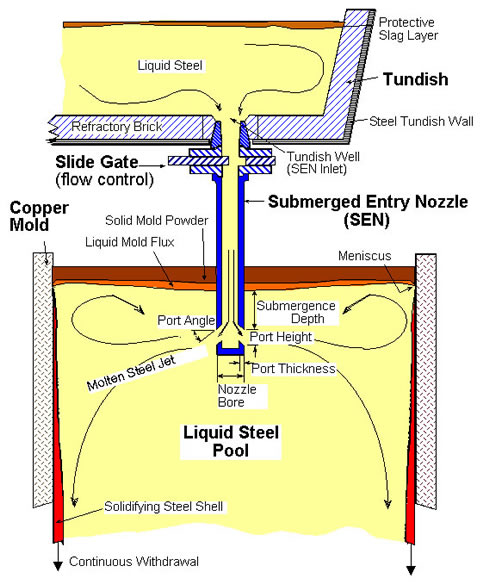

Continuous casting technology is currently the most efficient method of casting steel worldwide. Consequently more than 90 % of world steel is produced through the CC route

With the development of new markets and steel applications, the challenges to produce steel at higher casting speeds meeting stringent quality demands have increased manifold.

One of the most critical products used during continuous casting of steel to achieve the ever increasing demand for productivity and quality is the Continuous Casting Mould powder.

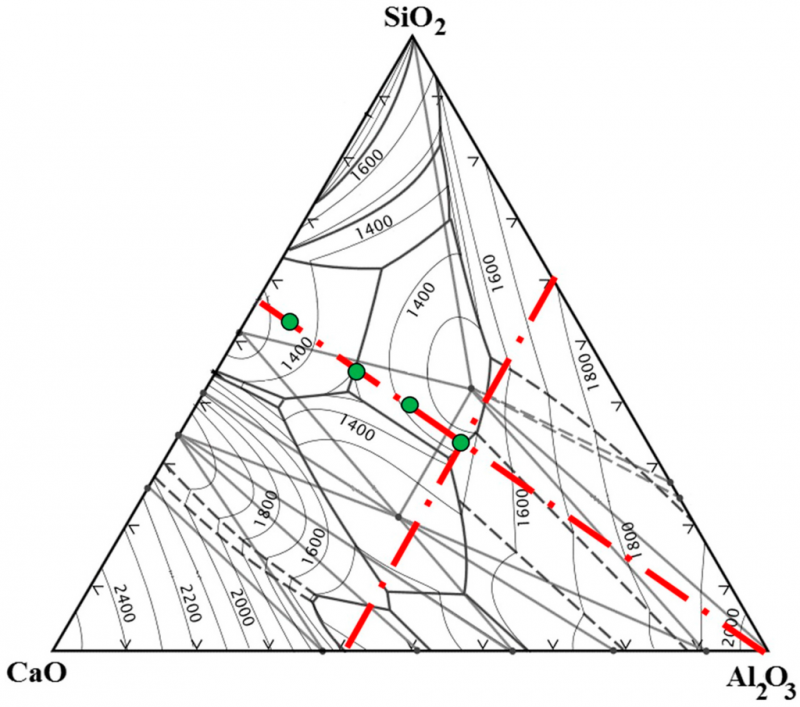

Granulated mould fluxes with optimum combination of physical, thermal, chemical and numerous critical properties determine the successful casting of steel as per modern day standards

- QMAX GR - The premium range of Mould Fluxes in Granular Form

- State of the art plant adopting the Spray Drying Technology

- Strong Quality and R and D focus with modern analytical and testing facilities

- Technical team with impeccable credentials and dedicated Product Engineers.Continuous customer interaction for optimisation of thermal and chemical properties of the product

- Available the entire range of products from Low Carbon,Medium Cabon,Peritectic,High Carbon and CSP grades for billet,bloom and slab casters

- Company firmly entrenched in the market with impressive customer list including some of the biggest Steel Conglomerates in India